-40%

BLDC Permanent Magnet Motor (Generator) 3.57kW 48V 10,000RPM

$ 1452

- Description

- Size Guide

Description

BLDC Permanent Magnet Motor (Generator) 3.57kW 48V 10,000RPMModel #

TGM4875

Description

BLDC Permanent Magnet Motor (Generator)

3.57kW 48V 10,000 RPM 3 Phase

Motors are one tenth the size and weight of a comparable power induction motors.

Ultra-low vibration with best in class positioning accuracy

Iron-less composite stator results in truly zero cogging torque.

Motor can be operated as servos, steppers, with speed control, or open loop.

When operated as a motor best performance is obtained with high frequency sinusoidal drives

External inductance is recommended per phase when operated with conventional <40 kHz drives

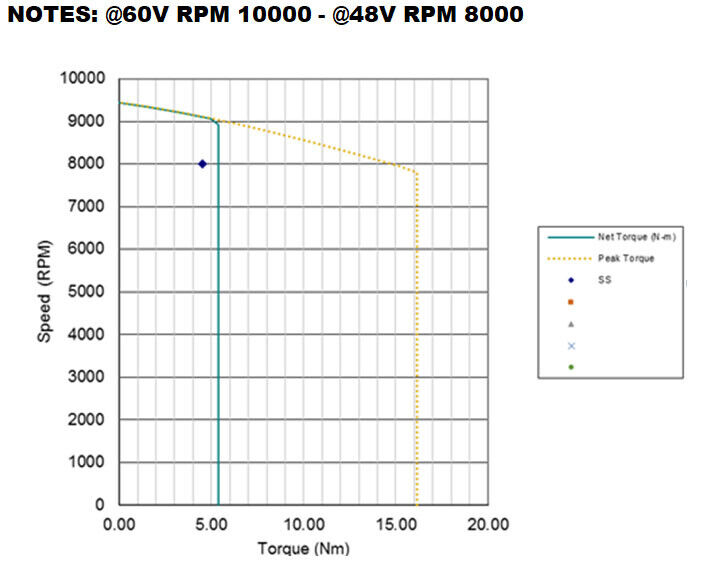

SPECIFICATIONS:

Max continuous torque (Nm): 4.26

Max permissible speed (RPM): 10800

Max continuous shaft power (kW): 3.57

Max efficiency (%): 91%

Max. Stator temperature (C): 120

Peak torque - 1s (3s) (Nm): 17.47 (10.5)

Winding Configuration

Max continuous current Arms

Parallel ∆: 72.5

SYM: I

Voltage constant Vpkl-l/(rad/s)

Parallel ∆: 0.046

SYM: Ke

Voltage constant Vpkl-l/kRPM

Parallel ∆: 4.8

SYM: Ke

Torque constant Nm/Arms

Parallel ∆: 0.065

SYM: Kt

Motor Constant Nm/√W

Parallel ∆: 0.330

SYM: Km

Terminal resistance Ω

Parallel ∆: 0.020

SYM: R

Terminal Inductance μH

Parallel ∆ 1.7

SYM: L

Motor Drive Voltage Vbus

(RPM*Kv*π/30+Torque/Kt*R)*1.2

Generator Terminal Voltage Vrms

(RPM*Kv*π/30-Torque/Kt*R)/Sqrt(2)

MECHANICAL SPECIFICATIONS

Max outer diameter in (mm) 7.169 (182)

Through hole diameter in (mm) 6.341 (161)

Total axial height in (mm) 1.539 (39)

Rotor mass lbs. (kg) 1.159 (0.526)

Stator mass lbs. (kg) 0.504 (0.228)

Part set mass (rotor & stator) lbs. (kg) 1.663 (0.754)

Total motor assembly mass lbs. (kg) 2.8 (1.27)

Rotor Inertia lbm-ft2 (kg-m2) 9.41E-2 (3.97E-3)

Hubs, Shafts, Bearings, and Mounts

Motors allow for a wide variety of mounting configurations to be used. Solid Shafts of different diameters, shafts with special steps, indentations, key-ways or other features can be accommodated. Hub and bearing configurations can be designed for optimum integration into your mechanism. While mounting hardware is normally fabricated from hardened steel, other materials can be used as well, including aluminum, brass and titanium. Hubs and mounts can attach to the rotor via screws into threaded holes in the Rotor, or they can be press-fit into the Rotor body, depending on the design. Shafts attach to the hub by various means to fit the application. Dimensions, materials, designs can be varied greatly and will depend on the application.

Domestic Return Policy

All refunds are made upon receipt of item/s after inspection and testing