-40%

60KTYZ Permanent Magnet Motors Synchronous Gear Motor Bracket AC220V 1.2~110RPM

$ 2.58

- Description

- Size Guide

Description

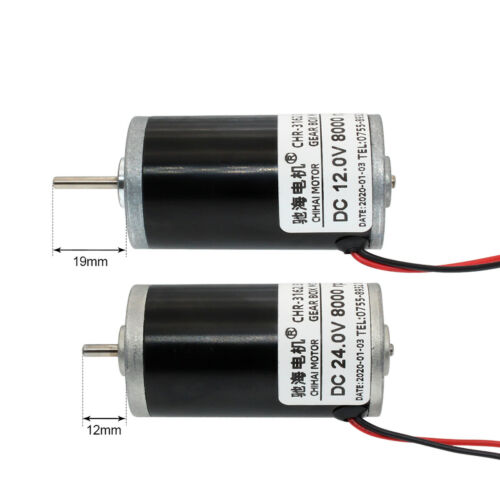

60KTYZ Permanent Magnet Motors Synchronous Gear Motor Bracket AC220V 1.2~110RPM● Model:

60KTYZ

● Size: φ60 X 60mm

● Eccentric shaft diameter 7mm

● Power supply: AC220V

● Input power: 14W

● Power mode: AC

● Running speed: Low speed motor

● Application: Universal

● Number of power phases: Single-phase motor

● Installation structure type: Vertical

● Function type: Drive motor

● Protection type: Open type

● Insulation class: E class

● Power type: AC motor

● Structure and working principle: Permanent magnet gear reduction synchronous motor

AC 220V Rated speed

1.2 rpm

Rated torque

70kg.cm

AC 220V Rated speed

2.5 rpm

Rated torque

60kg.cm

AC 220V Rated speed

5 rpm

Rated torque

40kg.cm

AC 220V Rated speed

8 rpm

Rated torque

30kg.cm

AC 220V Rated speed

10 rpm

Rated torque

20kg.cm

AC 220V Rated speed

15 rpm

Rated torque

14kg.cm

AC 220V Rated speed

20 rpm

Rated torque

10kg.cm

AC 220V Rated speed

30 rpm

Rated torque

7.5kg.cm

AC 220V Rated speed

50 rpm

Rated torque

4 kg.cm

AC 220V Rated speed

60 rpm

Rated torque

3.5kg.cm

AC 220V Rated speed

80 rpm

Rated torque

2.6kg.cm

AC 220V Rated speed

110 rpm

Rated torque

1.8kg.cm

Features:

Low power consumption, high torque, low noise, small size, light weight, easy to use, controllable forward and reverse directions, etc.

Mainly used in:

Monitor pan/tilt, electric equipment, heating and cooling valves, automated instruments, electric models, electric advertisements, mahjong tables, screen machines, plastic machines, money counters, barbecue equipment, electric summons devices and all low power Run the equipment at a low constant speed.

Buyer's Note:

1.

Make sure that the motor voltage is correct before use, and if it is a DC motor, also confirm whether the power supply current is sufficient.

2.

It can not be overloaded. The reasons for overloading are mainly divided into two parts, torque and shaft force. The load torque should not exceed the rated torque of the motor, and the shaft force should not exceed the axial and radial allowable force of the shaft. After the load is applied, the measured current of the motor cannot exceed the rated current. Generally, the motor must be equipped with a fuse to avoid overloading the motor.

3.

Do not store or operate in a high temperature or humid environment, and do not place it in corrosive gas, which will reduce the performance of the motor.

4.

When assembling transmission parts such as gears and pulleys on the motor shaft, do not knock abnormally when pressing in.

5.

When soldering is required on the motor terminals of the positive and negative poles of the power supply, the temperature of the soldering iron is 340°C±40°C, and the heating time is within 3 seconds, and the plastic cannot be deformed. During work, let the solder point flow into the motor or break the end of the wire. Deterioration of motor function.

6.

When installing the motor, pay attention to whether the screws are too long, and prevent the long screws from pressing the parts inside the motor.

7.

Torque concept: For example, when driving the pulley, the torque of 10KG.CM, the pulley radius is 1CM, the belt has 10KG pulling force, and if the pulley radius is 5CM, the belt has only 2KG pulling force.

8.

Common units: 1N.M=10KG.CM==0.1KG.M, 1HP=750W, 1W=1V.A

☎️☎️ ☎️ (If you need other size, you can chat with us privately.)☎️ ☎️ ☎️

About packaging

:

Shipment according to your choice.

Notes:

✔️

Large quantity accepts various sizes and can be customized.

📞If you can't find the relevant series of goods, you can ask us. We will be happy to help.

✔️If you need to buy more than one item, you can add a shopping cart first, and there will be a bigger discount.

📞Purchasing different products may result in abnormal shipping costs. If the shipping cost is too high, please contact us.

✍The pictures are for reference only, please choose your requirements (size, quantity).